Laser Welding Advantages

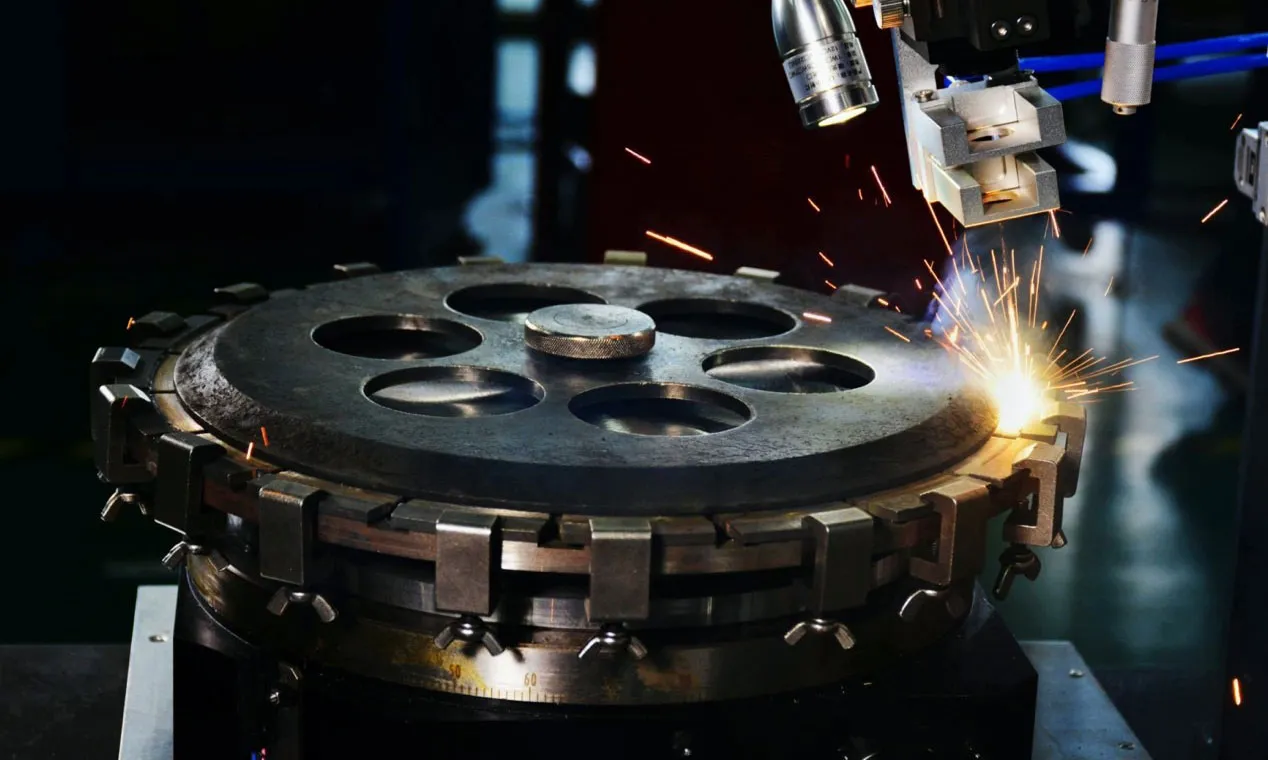

Laser welding offers high precision and minimal deformation

Laser welding minimizes deformation and ensures clean and strong joints. This method is ideal for a wide range of industries where high quality and result reliability are essential. It is fast, requires minimal operator experience, easily integrated into production processes offering both economic and environmental benefits - reducing costs and minimizing waste.

Up to 14 times faster welding compared to MIG/MAG and TIG methods.

Welding of steel, stainless steel, aluminium, copper and other materials.

Joins materials from 0,1 ‑ 10 mm without deformation and twisting.

Saving shielding gas consumption - nitrogen used for all materials.

Energy saving compared to electric arc welding technologies.

Low weld porosity and excellent molten bath protection.

Water cooling allows continuous operation without the risk of overheating.

Welding head equipped with a motorized oscillation system for precise beam control.

The laser can be used not only for welding, but also for cutting and cleaning.

Components from top European and global manufacturers.

Showrooms

Visit one of our showrooms and try laser welding technology directly on your own materials with the assistance of our technicians. Take the opportunity to consult your specific requirements with experienced industry experts.

- ✓The wire feeder is integrated into the machine, additional material with diameters of 0,8 - 1,6 mm can be used.

- ✓Each machine comes with a welding helmet with protective glass and self-dimming module for maximum safety during laser welding.

- ✓The machine comes with accessories including 10 protective lenses, a set of tips, a machine cover, and a stand for resting the welding head.

- ✓Welding parameters are possible to be set in detail on the display interface completely in English language.

- ✓Welding can be performed as spot welds or continuous seams up to 55 mm wide, with options to set intervals for pulse welding.

- ✓Multiple safety protection with automatic beam shut-off function when the nozzle moves away from the weldment.

- ✓You can test FANTECH machines in the showroom located in the company TigTech s.r.o. in Opava, where the welders are actively used in production.

- ✓Installment payment plan available for up to 6 months - the welder can pay for itself while in use.